Hyundai EV Rally Car

NEW ZEALAND’S #1 RALLY TEAM – Paddon Rallysport

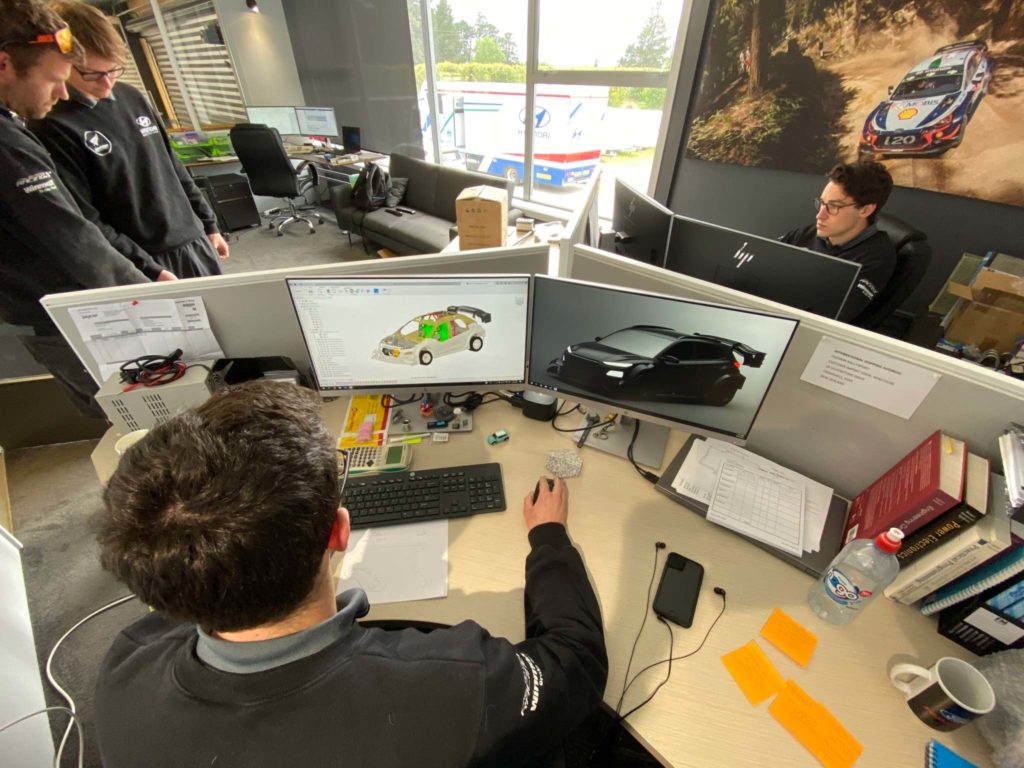

The future is coming and the future is here at Paddon Rallysport Group. After the initial idea come together in 2017, a group of some of the brightest young engineers and technicians was formed in late 2018 to begin the project to construct one of the first EV Rally Cars in the world.

While EV technology already exists in several forms of motorsport, rallying presents the biggest challenge to make this ever evolving technology work in the most demanding of motorsport environments. It’s about combining performance, range and reliability into one package. At PRG the design concept is to create an EV platform that is not only fast and spectacular, but one that can compete in a traditional rally format up against normal IC competition.

Working with our technical partner STARD, PRG will then develop a lot of the systems and some unique technology that sets our EV project apart. New Zealand also provides the best test facilities on our back door step – with an international race circuit at our facility and gravel roads stretching around the mountains surrounding our Central Otago base.

Hyundai EV Rally Car Specs

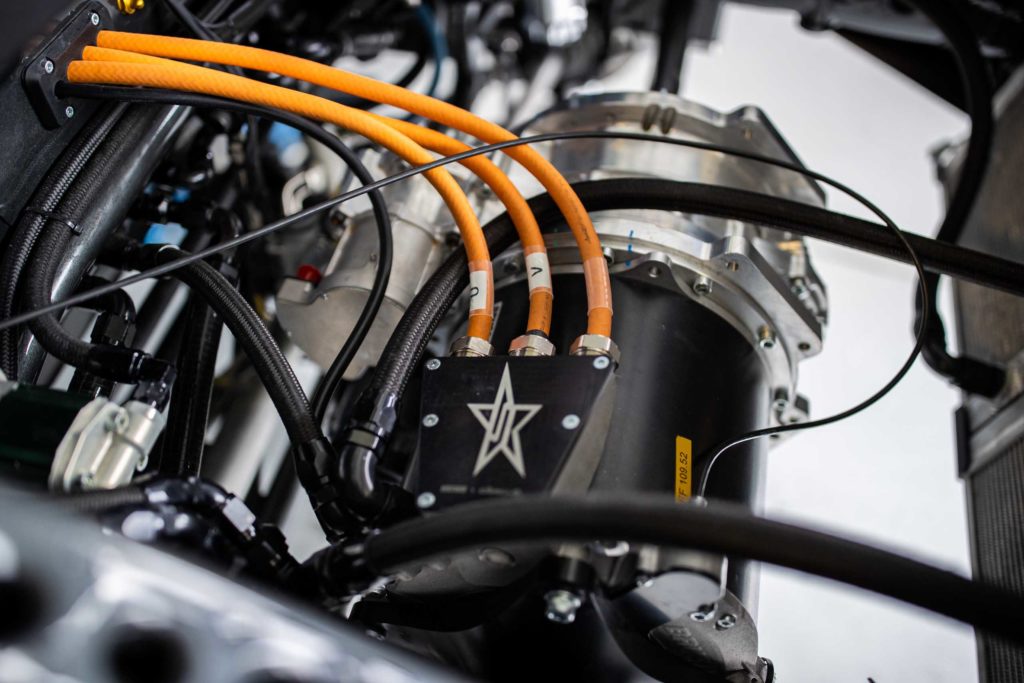

| Motors | Brusa BLDC Motor |

| Potential configuration 2, 3 or 4 motors | |

| Each motor peak power 220kw | |

| Up to 1,100Nm torque | |

| Customized cooling system | |

| Customized front/rear torque vectoring | |

| Tyres | Pirelli range |

| 15' Gravel, 18' Tarmac | |

| EVO Corse lightweight Alloy wheels | |

| Cockpit | Racetech seats, belts, steering wheel |

| MoTec M1 management system | |

| MoTec PDU and driver displays | |

| MoTec keypad | |

| Chassis / Suspension | Front / Rear EXT MacPherson struts with 5 way adjustable dampers (new technology) |

| Steering electric power-assisted rack and pinion | |

| Braking system ventilated Brembo disc brakes (355mm on tarmac; 300mm on gravel), Air-cooled 4-piston calipers | |

| Handbrake Hydraulic control | |

| Transmission | Twin transmission |

| Paddle shift gear selection - MoTec controlled | |

| Driver controlled torque settings | |

| Chassis / Bodywork | Steel bodyshell with welded multi-point chromoly roll cage. Extensive chassis strengthening |

| Bodywork Steel and composite fiber panels | |

| UC designed Aero package for a combination of down-force and reduced drag | |

| Weight | Expected weight approx 1500kg (with battery) |

Our EV Project Timeline

January 2019

New team base acquired and setup at the spectacular Highlands Motorsport Park with direct access to international race circuit. Perfect testing and development facilities.

Soon after 6 young engineers and technicians join the team including Matt, Rory, Ben, Jack, Mike and Vanessa. The basis was now in place to push forward on the EV concept that had spent the last 12 months on planning.

August 2019

At a worldwide media event streamed around the world, we share our vision and project to the motorsport community.

While the design phase was well under way at this point, the physical build had yet to start. Making sure all the boxes were ticked, we analysed the perfect chassis and geometry using data from existing cars and simulation data utilizing the whole new weight distribution of the car given the extra weight of the batteries.

At this time we also took delivery of a brand new Hyundai Kona to be used as a donor car.

October 2019

After 8 months of design and simulation, the chassis and geometry design was complete. This meant that the chassis build could start with confidence.

Design continues working alongside STARD on the systems and drive-line of the car and the all important battery pack.

The first prototype battery will be a smaller pack to allow us to simulate power use once the car is up and running to incorporate the full size rally battery during 2020.

November 2019

Our technicians Mike and Ben got to work on preparing the body shell which will include over 500 hours of work over the coming months.

After stripping the brand new car to a bare shell, work then began on lightening the shell as much as possible to compensate for the extra weight of the batteries.

Then, after making the Jig, strut towers and suspension points are inserted before work begins on a whole new floor and battery mounting to allow for quick battery changes.

February 2020

Chassis construction ramps up with finalised roll-cage and floor design.

The chromoly cage that is tig welded has also been designed to strengthen the subframe pick up points and to support the floor where the battery will be mounted.

Engineers also are close to finalizing designs of auxiliary components including cooling system and power steer system.

Suspension design has been confirmed with our partner EXT Shox and construction under way.

Our components from technical partner, STARD also arrived including transmissions, motors and inverters.

May 2020

Body shell now complete with roll cage, strut towers and all suspension points. This meant dummy fitting of subframes and major components can now start.

Over past months sub-assembly and construction has also been busy getting each component ready to be fitted to the chassis when ready. This included the delivery of our aero kit that was developed in conjunction with the University of Canterbury.

Systems and components now begin bench testing before dummy fitting the car together.

August 2020

A big part of an EV car is the electrics. While working with our technical partner gives us a base to work from, we have a big task ahead to build a new high voltage and low voltage wiring loom for the car, incorporating all the general road requirements of a car to help make it suitable for future rally and compliance.

Part of the electrics process is also bench testing and all the schematic drawings to give us a base for future developments and work. Also work continues on our unique sound generator and electrical power steer system.

September 2020

A big part of the project with a new and exciting car like this is to make sure it catches the eye, but also have a aerodynamic package that creates good downforce while generating less drag.

Working with UCM and Southern Ocean boat builders, we have continued to develop our full carbon fibre body kit. Coupled with the exterior, we have also worked a lot on the interior to ensure we have unique design and functionality to ensure the car has flare and is not just ‘another car’.

October 2020

After over 10,000 hours of design and manufacturing, our Kona EV is assembled for the last time to conduct the initial tests and filming days, before official reveal to the world on 4 November, 2020.

While still very raw, its a hugely proud moment for the team as we lead the way in EV technology in a rally environment.

The work doesn’t stop here however, with an extensive test and development program over the next 12 months to exploit the most from the car, and proof the technology in rallying.

November 2020

Following the official reveal of the Hyundai Kona EV, the team took the future of the sport to New Zealand’s biggest gravel event in 2020. Built on the farm of a well recognised rally family, Jack’s Ridge Rallysprint was the perfect place to debut to the public.

Being it was purely demonstration, Hayden targeted putting on a show for the crowd. Taking the car over the large jump at the centre of the arena flat. The first time the cars jumped and in front of 5,000 spectators.

April 2021

In 2021 the car made it’s debut on an official rally stage, again as a demonstration. Lining up on the notorious Super Special Stage in downtown Dunedin at the Otago Rally. The team had the Dunedin Mayor running shotgun and with gravel tyres on, Hayden slid the car around the streets of the city.

May 2021

Following Otago Rally, the team brought the car north to Rally Whangarei again to demonstrate the vehicle on the Super Special Stage. But this time, it was all gravel.

Though only demonstration, the time reflected the true pace of the car. Beating Hayden’s time in the internal combustion car by over a second over a mere couple kilometres.

Knowing now the car had the pace, it was now time to get stuck into some initial development in the hopes of an official event debut later in the year.

October 2021

The biggest moment in the cars short history. In October 2021, we took the Hyundai Kona EV to challenge the Waimate 50’s Horsepower Hillclimb. Lining up against plenty of high horsepower hillclimb specialists in our rally specification car, we were unsettled around our chances of taking the win.

Alongside this, the team debuted it’s all new sound device made completely mechanically. Giving life to the EV with it screaming up the hill.

An incredible final run and huge team effort gave the team and car its first win on its debut competitive event. One the team will never forget.